CONTROLS FOR WET DUST COLLECTION

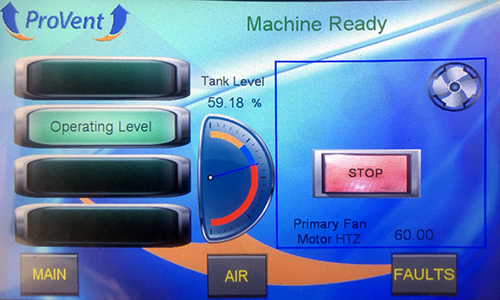

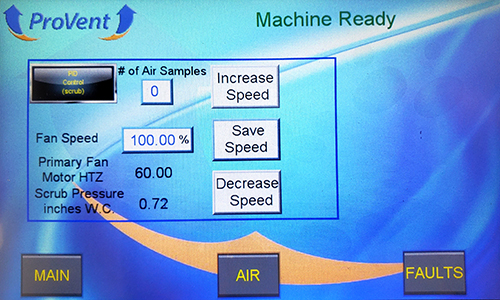

The ProVent HMI Touch Screen Control is the latest advancement in dust collector technology. The HMI allows for real-time visual monitoring of the dust collector systems. There are several advantages that can be gained by this technology.

-

Ultrasonic Water Level Control

- Provides precise control of the water level increasing efficiency.

- Stable airflow

-

Low Voltage Components

- All components such as solenoid valves, temperature sensors, airflow monitors can be operated at 24V

- Increased safety

-

Variable Frequency Drive

- Continuously monitors pressure consumed by the dust collector to create the most efficient wet dust collector on the market

- Self adjusts to after-filter loading to maintain efficiency and airflow.

OPTIONAL CONTROLS

- REMOTE HMI – Provides a second HMI control to be placed remotely from the dust collector for applications where the dust collector is not conveniently located near the process.

- POWER DRAIN/CLEAN/REFIL – Automatically drain, wash, refill options to maintain cleanliness inside the dust collector. Various options of this sequence can be set up by the user. Note: Available on wet dust collectors 3,000 CFM and under with the hopper / power drain options.

- PRO – NFPA PACKAGE – Continuously monitors airflow, motor temperature and after-filter temperature (if provided). Shuts the equipment down, sounds alarm and flashes a warning light when any of these components recognizes failure. Additionally, provides a connection to send a signal from the dust collector to the dust producing equipment of a shut down.